The SPPDG Proof-of-Concept and Prototyping Lab Facilities contain five distinct areas: Cleanrooms; Hand soldering area; Radio Frequency Anechoic Chamber; Shield Room; Machining rooms. Each area is shown in more detail:

3 Cleanrooms for Electronics Assembly and Test: Bay design, 6784 ft2, maintained at 70 +/-5 F, 40 +/- 5% RH; chemical hood, compressed air, DI water, N2. Allows sensitive parts to be assembled and to remain out of dry boxes for extended testing.

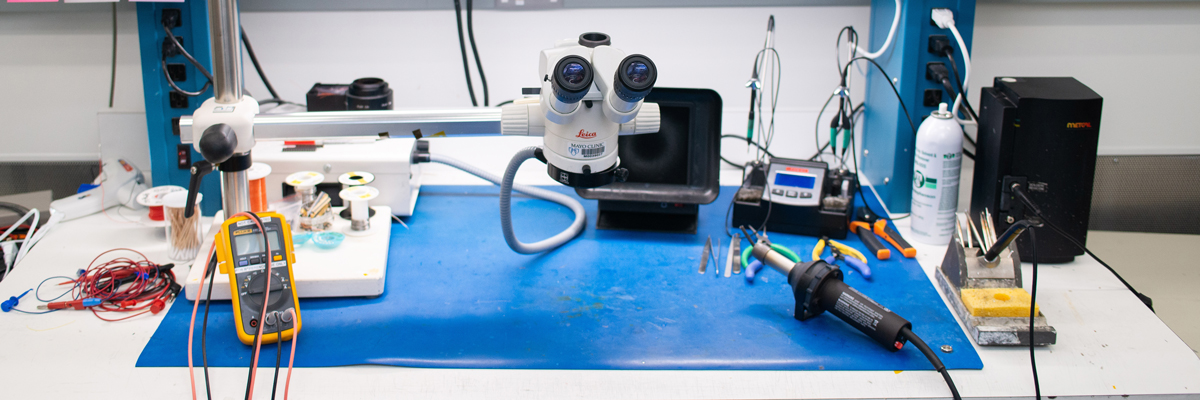

Hand Soldering Set-Ups: Two set-ups, each outfitted with a Leica microscope, JBC Tools NASE-1C soldering station with nano tweezers, and Metcal soldering rework station. Soldering stations are temperature controlled, reducing risk of component damage and providing fine pitch soldering and rework capability.

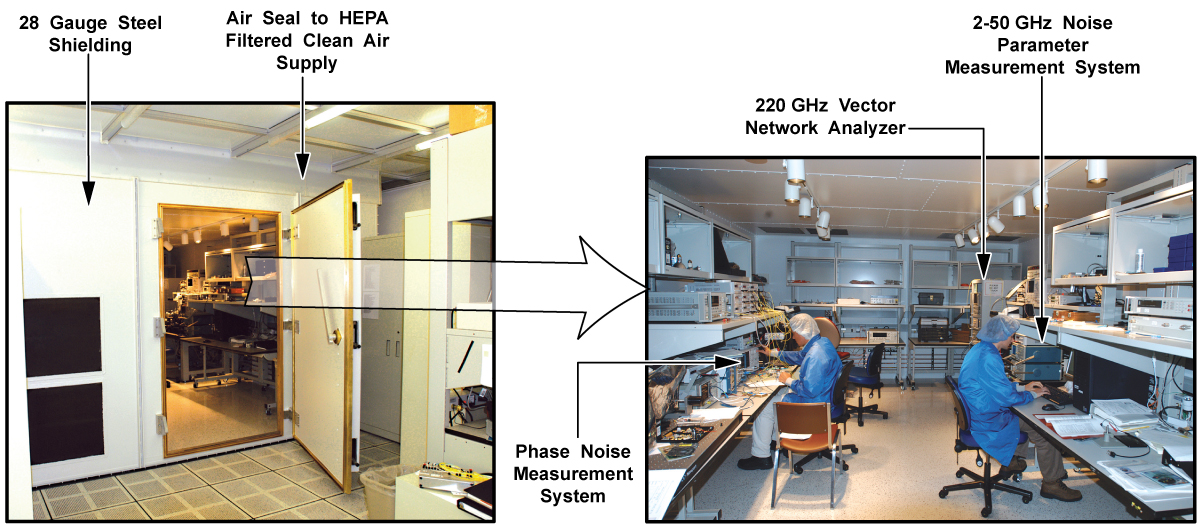

ETS Lindgren Series 81 Shield Room: 15’ x 22’ x 8', designed to attenuate external radio frequency interference, measured at greater than 100 dB attenuation from 1 kHz to 10 GHz.

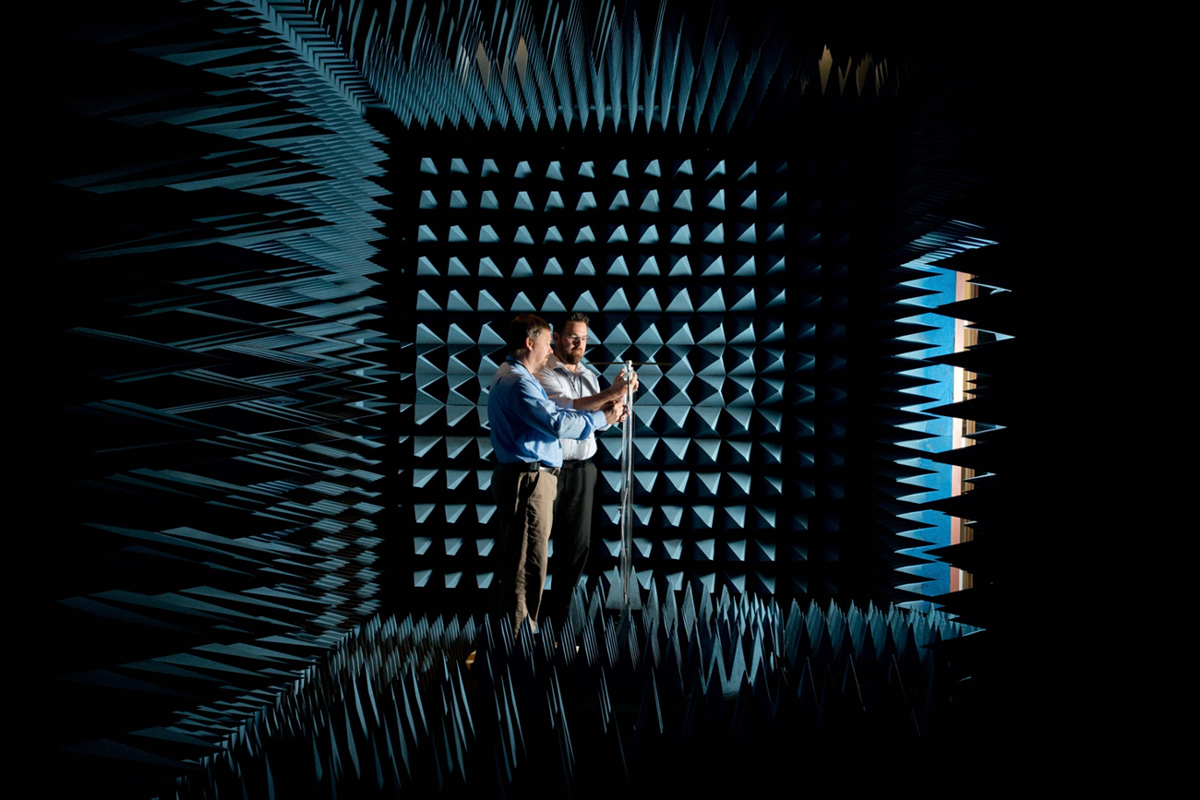

Radio Frequency Anechoic Chamber: 12’ x 12’ x 24’, designed to function in the “far field” over a frequency range of approximately 700 MHz to 40 GHz.

Machining/Prototyping: 157 ft2 area for milling, 322 ft2 area designated for other machining support.

Specialized Testing Areas: 525 ft2 of space consisting of 3 separate rooms that can be reconfigured as needed.

Information updated Wednesday, November 17, 2021

Any use of this site constitutes your agreement to the Terms and Conditions and Privacy Policy linked below.

"Mayo," "Mayo Clinic," "MayoClinic.org," "Mayo Clinic Healthy Living," and the triple-shield Mayo Clinic logo are trademarks of Mayo Foundation for Medical Education and Research.